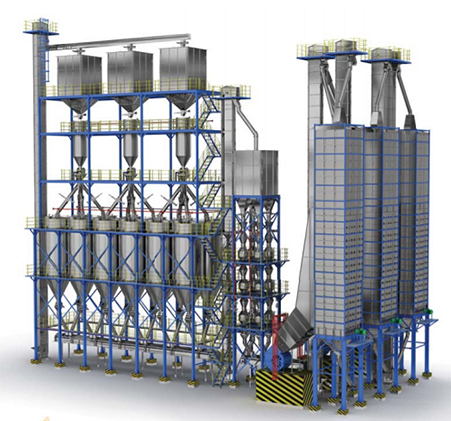

Paddy Parboiling System and Dryer

Paddy Parboiling System and Dryer

A paddy parboiling system and dryer is an integrated setup used in rice processing to parboil and dry paddy efficiently before milling. Parboiling involves soaking, steaming, and drying the paddy, which improves its milling yield, nutritional value, and storage stability. This system is essential in the production of high-quality parboiled rice.

Features of a Paddy Parboiling System and Dryer

Paddy Pre-Cleaner

Soaking Tanks

Steaming System

Paddy Dryer

Removes excess moisture from steamed paddy, reducing it to safe storage levels (12–14% moisture content).

Key Components

Parboiling Tanks

Control Systems

Advantages of Paddy Parboiling System and Dryer

Reduces grain breakage during milling, leading to higher head rice yield.

Nutrients from the husk and bran layers migrate into the grain during parboiling.

Reduces moisture content and inhibits fungal growth and pest infestation

Ensures consistent cooking and drying for better market acceptance

Modern systems incorporate heat recovery and optimized processes to reduce fuel consumption